OSZCZĘDNOŚĆ WODY

LEPSZA JAKOŚĆ MYCIA

WIELE ZASTOSOWAŃ

OSZCZĘDNOŚĆ WODY

LEPSZA JAKOŚĆ MYCIA

WIELE ZASTOSOWAŃ

OSZCZĘDNOŚĆ WODY

LEPSZA JAKOŚĆ MYCIA

WIELE ZASTOSOWAŃ

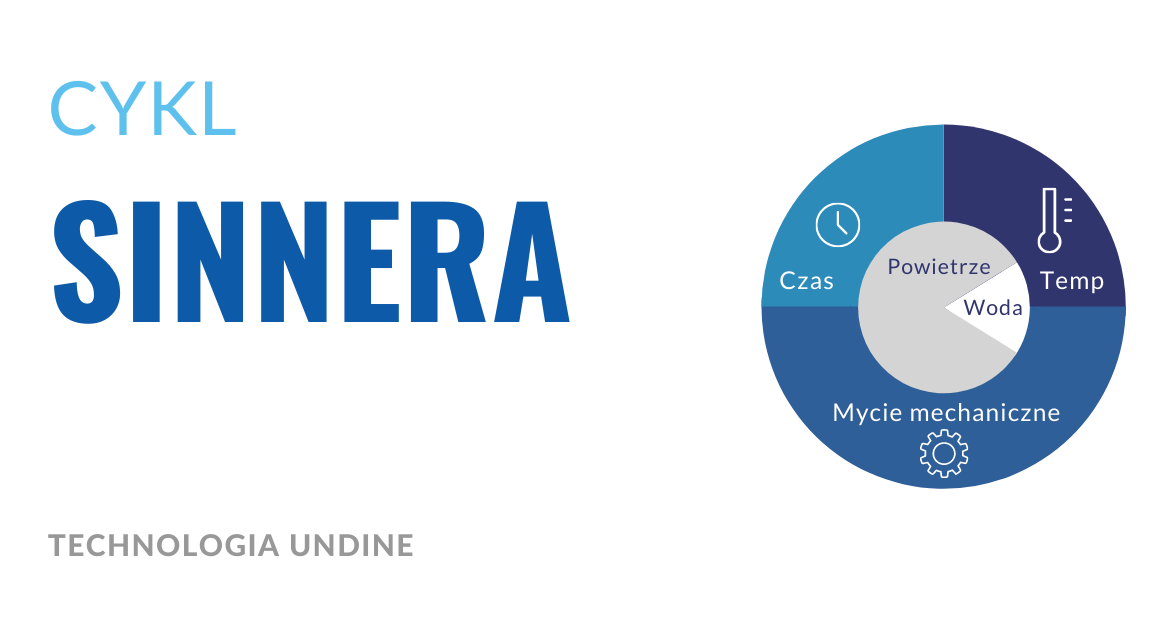

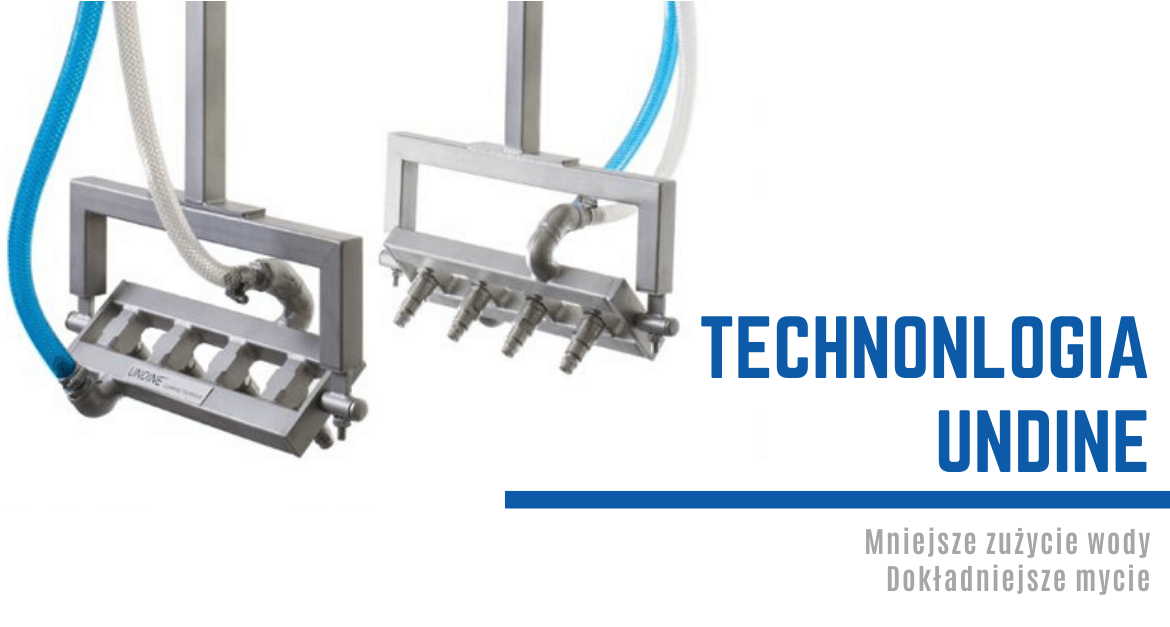

O TECHNOLOGII UNDINE

Technologia Undine ® jest wyjątkowym rozwiązaniem, które w bardzo prosty sposób może przynieść Twojej firmie spore oszczędności i znacznie poprawić jakość mycia. Myjki Undine mają wiele zastosowań. Wykorzystywane są m.in. w zakładach drobiarskich do mycia tuszek, strzemion oraz schładzania produktów. W przemyśle owocowo warzywnym Undine wykorzystuje się do czyszczenia owoców i warzyw, ale również podajników taśmowych czy innych elementów wyposażenia. Dzięki opatentowanym komorom mieszania wody i powietrza mycie jest dużo bardziej efektywne, a ilość zużywanej wody i energii znacznie mniejsza.

O TECHNOLOGII UNDINE

Technologia Undine ® jest wyjątkowym rozwiązaniem, które w bardzo prosty sposób może przynieść Twojej firmie spore oszczędności i znacznie poprawić jakość mycia. Myjki Undine mają wiele zastosowań. Wykorzystywane są m.in. w zakładach drobiarskich do mycia tuszek, strzemion oraz schładzania produktów. W przemyśle owocowo warzywnym Undine wykorzystuje się do czyszczenia owoców i warzyw, ale również podajników taśmowych czy innych elementów wyposażenia. Dzięki opatentowanym komorom mieszania wody i powietrza mycie jest dużo bardziej efektywne, a ilość zużywanej wody i energii znacznie mniejsza.

KOMORA MIESZANIA

Technologia Undine® w opatentowanych komorach miesza ze sobą strumień wody i powietrza.

WYSOKIE CIŚNIENIE

Prędkość przepływu wody w konwencjonalnej myjce przy 40 barach wynosi 120 km/h. Undine osiąga prędkość około 900 km/h.

MINIMALNE KROPLE

Dzięki wymieszaniu wody i powietrza i przy wysokim ciśnieniu dysze wyrzucają bardzo małe krople, które dają duże lepsze efekty mycia

Mniejsze krople dużo lepiej penetrują nierówności czyszczonych powierzchni. Mieszając wodę z powietrzem możliwe jest zredukowane zużycia wody nawet o 80% (w zależności od zastosowania). Prowadzi to również do minimalizacji powstawania aerozolu, który może zanieczyszczać inne powierzchnie. Dodatkowym atutem technologii jest to, że redukcja zużycia wody powoduje obniżenie ilość produkowanych ścieków, ale i kosztów energii potrzebnej podczas czyszczenia ciepłą wodą.

MOŻLIWOŚCI ZASTOSOWANIA

KURY

KACZKI

INDYKI

DROBIARSTWO

Myjki Undine montujemy w ubojniach drobiu na różnych etapach produkcji. Dzięki technologii Undine osiągamy bardzo dobre efekty higieniczne. Regulowane dysze pozwalają na precyzyjne nakierowanie strumienia wody. Silny strumień uzyskany poprzez wymieszanie wody ze sprężonym powietrzem dokładnie czyści nieregularne powierzchnie tuszek. Tuszki są myte na wielu etapach produkcji: przed oparzelnikami, za skubarkami, przy otwarciu powłoki brzusznej, za patroszarką, za wolowaniem oraz na końcu linii patroszenia. W rezultacie tuszki są bardzo dokładniej myte i ich okres przydatności się wydłuża. Zastosowanie myjek Undine w ubojniach przynosi znaczne oszczędności. Zastosowanie myjek na 5 różnych etapach mycia przy użyciu Undine konsumuje mniej wody niż 1 konwencjonalne urządzenie. Przemysł drobiarski wymaga wykorzystania ogromniej ilości wody, dlatego jej redukcja jest pożądana nie tylko ze względów finansowych, ale i ekologicznych. Możliwe jest ograniczenie zużycia wody w trakcie produkcji nawet o 50%. Komora mieszania wody i powietrza sprawia, że krople są znacznie mniejsze, a ich prędkość osiąga nawet 900 km/h. Wszystko to powoduje, że efektywność mycia jest znaczenie lepsze i korzystniejsza finansowo.

Posiadamy blisko 30 rodzajów myjek tuszek, które wykorzystywane są na linii patroszenia, skubania czy schładzania. Ponadto dysponujemy myjkami do mycia elementów wyposażenia ubojni. Technologia Undine może być także wykorzystana do modernizacji myjek topowych producentów, takich jak Meyn, Linco czy Stork.

DELIKATNE

PRODUKTY

OWOCE I WARZYWA

Technologia Undine świetnie nadaje się do mycia produktów spożywczych, takich jak owoce i warzywa Mała średnica kropel o dużej prędkości nie tylko pozwala na dokładne umycie produktów, ale również gwarantuje że delikatne owoce nie zostaną uszkodzone mechanicznie. Poprzez indywidualne dozowanie wody i powietrza w komorze mieszania, system może być bardzo dokładnie modyfikowany w zależności od konkretnego zastosowania i stopnia zanieczyszczenia.

Uszkodzenia delikatnych produktów podczas mycia, szczególnie owoców i warzyw, mogą powodować, że nie będą one nadawać się do sprzedaży. Dzięki Undine już na etapie mycia można zmniejszyć ilość uszkodzonych produktów oraz dostarczać na rynek owoce i warzywa w znacznie lepszym stanie.

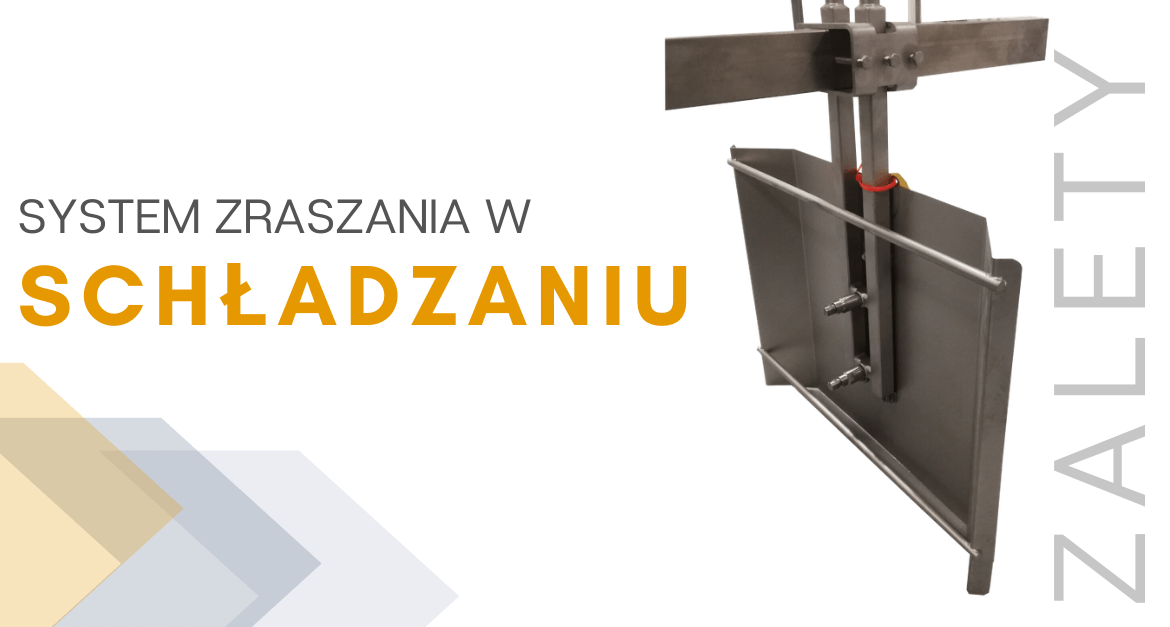

LINIE UBOJU

PATROSZENIA

SCHŁADZANIA

PODAJNIKI TAŚMOWE

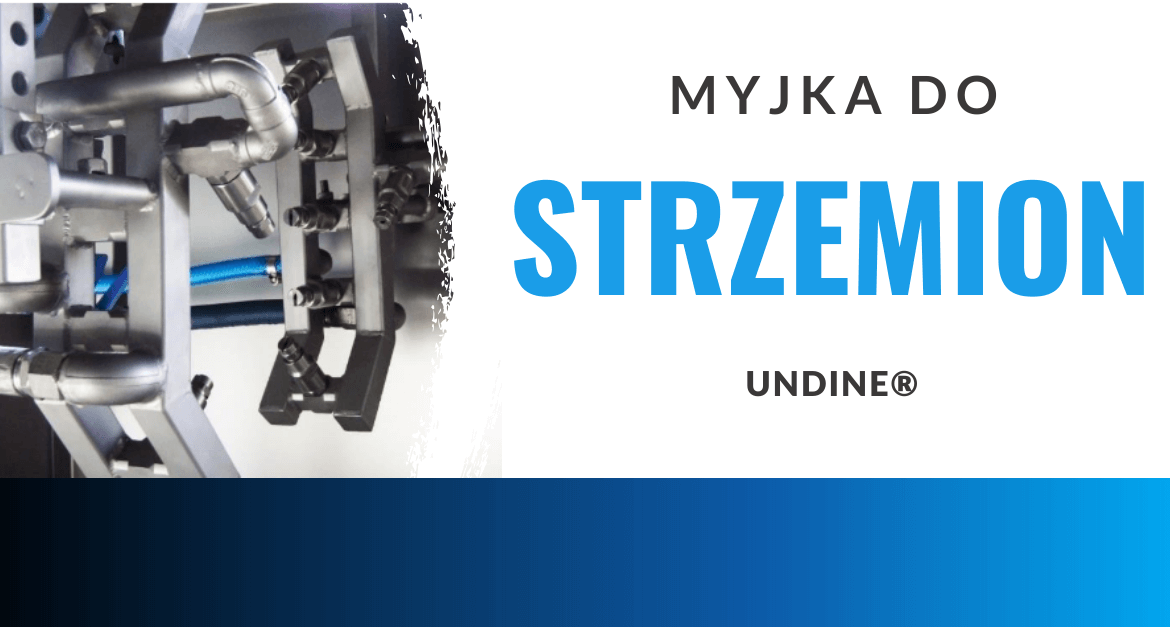

MYCIE PODAJNIKÓW I STRZEMION

Stosowanie myjek Undine nie ogranicza się tylko do produktów spożywczych. Technologia świetnie nadaje się także do mycia podajników taśmowych, które bardzo często ulegają trudnym zanieczyszczeniom. Do ich czyszczenia wykorzystuje się dużą ilość wody oraz środków chemicznych. W przypadku ręcznego czyszczenia, wymaga to także ogromnej pracy ludzi. Podczas mycia podajników taśmowych może dochodzić również do powstawania zanieczyszczeń krzyżowych innych elementów hali. Myjki Undine pozwalają wyczyścić te elementy przy redukcji zużycia wody, środków chemicznych oraz pracy ludzi, a w efekcie umożliwiają osiągnięcie najwyższego standardu czyszczenia.

WIEPRZOWINA

WOŁOWINA

RYBY

WOŁOWINA I WIEPRZOWINA I RYBY

Undine stosujemy wszędzie tam, gdzie wymagane jest dokładne mycie produktu. Nasze rozwiązania znalazły zastosowanie w zakładach produkujących wieprzowinę, wołowinę oraz ryby. Nasze modernizacje świetnie sprawdzają się w zakładach przetwórstwa rybnego, gdzie doskonale usuwają pozostałości po patroszeniu oraz śluz, zużywając przy tym 50% mniej wody niż standardowe rozwiązania. Jesteśmy w stanie dopasować nasze moduły do różnego rodzaju kabin natryskowych, oraz wykonać moduły na specjalne zamówienie klienta.

DO 10 RAZY BARDZIEJ HIGIENICZNE

MYCIE Z OSZCZĘDNOŚCIĄ WODY DO 70%

MOŻLIWOŚCI ZASTOSOWANIA

KURY

KACZKI

INDYKI

DROBIARSTWO

Myjki Undine montujemy w ubojniach drobiu na różnych etapach myci. Dzięki innowacyjnym komorom mieszania osiągamy wspaniałe efekty higieniczne. Regulowane dysze pozwalają na nakierowanie strumienia wody w konkretnym kierunku. W rezultacie tuszki są dokładniej myte i ich okres przydatności się wydłuża. Zastosowanie myjek Undine w ubojniach przynosi spore oszczędności. Przemysł drobiarski wymaga wykorzystania ogromniej ilości wody, dlatego jej redukcja jest pożądana nie tylko ze względów finansowych, ale i ekonomicznych. Komora mieszania wody i powietrza sprawia, że krople są znacznie mniejsze, a ich prędkość osiąga nawet 900 km/h. Dzięki temu lepiej penetrują one pory i nierówności mytych powierzchni. Jednocześnie zdmuchiwane są zanieczyszczenia ze zwilżonej powierzchni. Wszystko to powoduje, że efektywność mycia jest znaczenie lepsze i korzystniejsza finansowo.

Posiadamy blisko 30 rodzajów myjek tuszek, które wykorzystywane są na linii patroszenia, skubania czy schładzania. Ponadto dysponujemy myjkami do mycia elementów wyposażenia ubojni. Technologia Undine może być także wykorzystana do modernizacji myjek topowych producentów, takich jak Meyn, Linco czy Stork.

DELIKATNE

PRODUKTY

OWOCE I WARZYWA

Technologia Undine świetnie nadaje się również do mycia produktów spożywczych, takich jak owoce i warzywa. Małe krople, które są wyrzucane na zewnątrz pod odpowiednim ciśnieniem tworzą delikatny spray. Dzięki temu mycie jest dużo bardziej dokładne, a produkty nie są narażone na mechaniczne uszkodzenia. Poprzez indywidualne dozowanie wody i powietrza w komorze mieszania, system może być bardzo dokładnie modyfikowany w zależności od konkretnego zastosowania i stopnia zanieczyszczenia.

Uszkodzenia delikatnych produktów podczas mycia, szczególnie owoców i warzyw, mogą powodować, że nie będą one nadawać się do sprzedaży. Dzięki Undine już na etapie mycia można zmniejszyć ilość uszkodzonych produktów oraz dostarczać na rynek owoce i warzywa w znacznie lepszym stanie.

LINIE UBOJU

PATROSZENIA

SCHŁADZANIA

PODAJNIKI TAŚMOWE

MYCIE PODAJNIKÓW I STRZEMION

Stosowanie myjek Undine nie ogranicza się tylko do produktów spożywczych. Technologia świetnie nadaje się także do mycia podajników taśmowych, które bardzo często ulegają trudnym zanieczyszczeniom. Do ich czyszczenia wykorzystuje się dużą ilość wody, ale i środków chemicznych. W przypadku ręcznego czyszczenia, wymaga to także ogromnej pracy ludzi. Podczas mycia podajników taśmowych może dochodzić również do powstawania zanieczyszczeń krzyżowych innych elementów hali. Myjki Undine pozwalają wyczyścić te elementy przy redukcji zużycia wody, środków chemicznych oraz pracy ludzi, a w efekcie umożliwiają osiągnięcie najwyższego standardu czyszczenia.

DO 10 RAZY BARDZIEJ HIGIENICZNE

MYCIE Z OSZCZĘDNOŚCIĄ WODY DO 70%

REFERENCJE

REFERENCJE

KONTAKT

IWC International

Bedrijfsweg 38-40

8304 AZ Emmeloord

Nederland

Telefon: +31 (0) 527 745 932

Mail: info@iwc-international.com

Ton Winters +31(0)622 105 619

KONTAKT

IWC International

Bedrijfsweg 38-40

8304 AZ Emmeloord

Nederland

Telefon: +31 (0) 527 745 932

Mail: info@iwc-international.com

Ton Winters +31(0)622 105 619