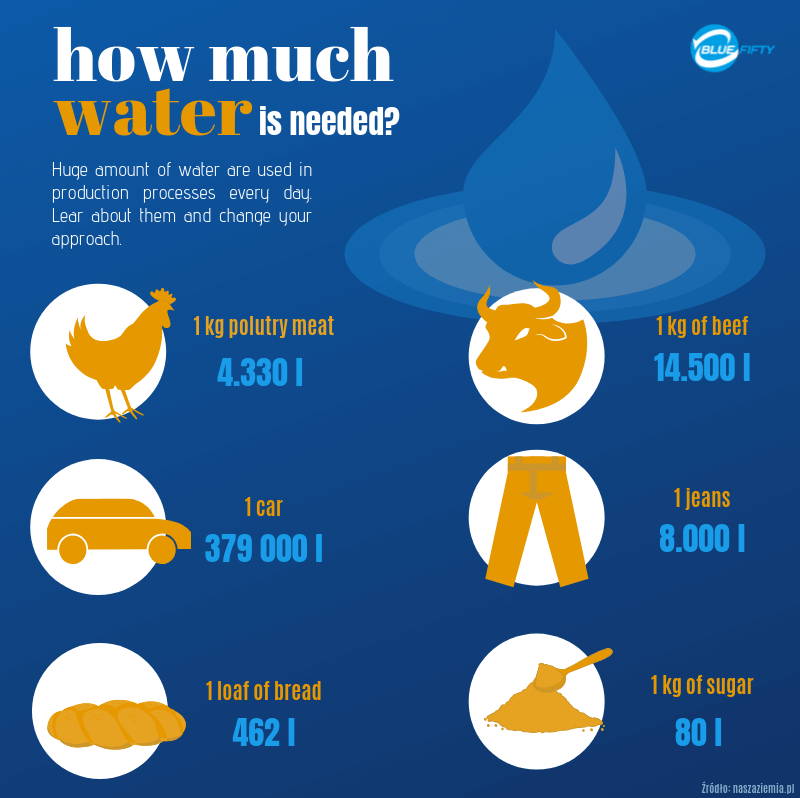

Nowadays, many companies all over the world are battling against a problem of significant water consumption. Huge amounts of water are every day used for instance in production of food or everyday items. Such high water consumption is a reason of high financial costs. It is also of no small importance for the environment because very often pollution gets into water. In many branches of industry, water is used to wash products (e.g. food) or equipment. IWC, a Dutch company patented the Undine technology and brought it to market. It reduces the usage of water used for cleaning up to 75%. At the same time, cleaning efficiency is higher than in a situation when the conventional solutions are used.

Necessity is the mother of invention – it all started with leeks

The founder of IWC Ton Winters possessing a leeks growing plant, was struggling with a problem of high water consumption on his farm. The local authorities were just about to refuse him a permission to continue his production, as he used huge amounts of water to wash his products. At the same time, one of his compressors was damaged and started to spray a mixture of water and air. It turned out that such a sprayed mixture of water and air effectively washed the vegetables. For Ton, it was an inspiration to create the Undine technology. At present, Ton is no longer a farmer but a successful, world-famous entrepreneur. Together with Tjerk Nijdam, he founded IWC, a company that develops and provides systems using the technology all around the world.

How do the Undine washers work?

Water and compressed air are mixed in the specially designed mixing chambers. As a result of mixing these two components in the chambers, the stream consists of very small needles of water running at an incredible speed up to 900 km/h, while in a conventional high-pressure cleaning it is only 140km/h.

Where can the Undine technology be applied?

The Undine technology is best suited for large industrial plants where huge amounts of water are used every day. It allows to reduce the amount of water up to 75%.

The Undine washers can be applied in various branches of industry. They are perfect for meat processing plants. Huge amounts of water are used to prepare each kilogram of meat. The Undine technology significantly reduces the amount of water and improves the quality of washing. The Undine washers improve product cleanliness and ensure hygiene.

Apart from meat factories, the technology works very well in fruit and vegetable factories. Normal high-pressure washers may damage the products which can lead to their faster decay. It also has a negative impact on their appearance. The Dutch technology allows not only to apply less water and energy but also causes less loss while cleaning, thus extending the shelf life of the products.

Undine can also be applied to clean other products or factory objects such as feeders, belts, shackles, containers and packaging. By reducing water consumption, it automatically reduces the amount of wastewater which also generates costs. Manual cleaning may also be replaced with Undine reducing the workload.

Summary of the benefits

The main feature of the Undine technology is reduction of water consumption. It is very important and even necessary nowadays. Not only for the economic reasons but also for the ecological ones. The usage of compressed air and water improves the efficiency of the cleaning process; it reduces water and energy consumption as well as the amount of waste. In addition, the food products or devices are cleaned more carefully thanks to the enormous speed of water and air. Cleanliness and hygiene are improved. In case of food products (meat, fruit or vegetables) the shelf life may be extended, because thanks to better and more gentle cleaning, food remains fresher for longer.

Undine in the Polish market

The Blue Fifty company has been installing the Undine washers in Poland since 2017. We improved the cleaning process by modernizing the current installations in 8 poultry processing plants. As a result, water consumption in these companies has been reduced as well as hygiene and cleanliness of products has increased.

Today more than 85 million m3 of water has already been saved worldwide thanks to the IWC Undine technology!